Introduction

In recent years, hemp-derived CBD (cannabidiol) has gained significant popularity for its potential therapeutic benefits. As a leading CBD producer, Rebellion CBD Co. follows a meticulous process to ensure the production of high-quality CBD products. In this comprehensive guide, we will delve into the step-by-step process of making hemp-derived CBD, from cultivation to extraction and product formulation. By understanding the intricacies of this process, we can gain insight into the dedication and expertise involved in creating top-notch CBD products.

Table of Contents:

Cultivation of High-Quality Hemp

- Selecting the Right Hemp Varieties

- Soil Preparation and Nutrient Management

- Planting and Growing Conditions

- Pest and Disease Management

- Harvesting and Drying

Extraction Methods for CBD

- 2.1 Decarboxylation

- 2.2 Solvent Extraction

- 2.3 CO2 Extraction

- 2.4 Winterization

- 2.5 Distillation

- 2.6 Isolation and Purification

Testing and Quality Control

- 3.1 Third-Party Lab Testing

- 3.2 Cannabinoid Profiling

- 3.3 Purity and Contaminant Testing

Product Formulation and Manufacturing

- 4.1 Full-Spectrum, Broad-Spectrum, and Isolate CBD

- 4.2 Choosing Carrier Oils and Other Ingredients

- 4.3 Flavoring and Aromatherapy Additives

- 4.4 Packaging and Labeling

Compliance with Regulations and Standards

- 5.1 Legal Compliance for Hemp-Derived CBD

- 5.2 Following Good Manufacturing Practices (GMP)

- 5.3 Adhering to Labeling Requirements

Transparency and Customer Education

- 6.1 Providing Detailed Product Information

- 6.2 Clear Dosage Instructions and Usage Recommendations

- 6.3 Educational Resources and Customer Support

Conclusion

Cultivation of High-Quality Hemp:

- Selecting the Right Hemp Varieties:

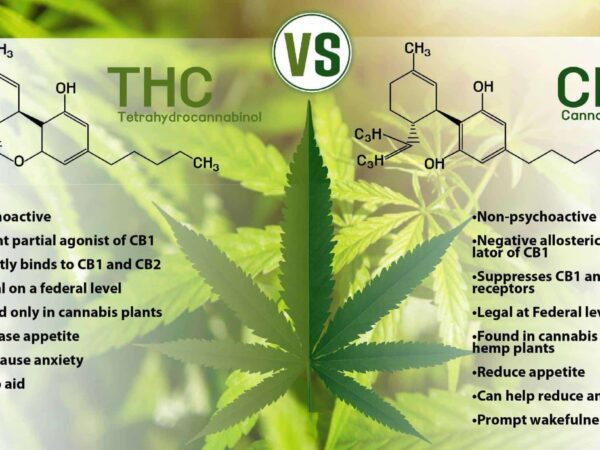

Rebellion CBD Co. carefully chooses hemp strains that are high in CBD and low in THC to comply with legal requirements. Varieties with desirable traits such as disease resistance, high yields, and cannabinoid profiles are selected for cultivation.

- Soil Preparation and Nutrient Management:

The cultivation process starts with preparing the soil by ensuring proper drainage, fertility, and pH levels. Rebellion CBD Co. follows sustainable farming practices and may incorporate organic amendments and crop rotation to maintain soil health.

- Planting and Growing Conditions:

Seeds or clones are planted at the optimal time, taking into account the local climate and growing conditions. Proper spacing and plant care techniques, including watering, pruning, and trellising, are implemented to promote healthy plant growth.

- Pest and Disease Management:

Rebellion CBD Co. employs integrated pest management strategies to protect the hemp plants from pests and diseases. This may involve the use of organic pest control methods, such as beneficial insects, and monitoring techniques to identify and address issues promptly.

- Harvesting and Drying:

The hemp plants are harvested at the right stage of maturity to maximize CBD content and minimize THC levels. After harvest, the plants are carefully dried to remove excess moisture without compromising the cannabinoid and terpene profiles.

Extraction Methods for CBD

- Decarboxylation:

Decarboxylation is a process that involves heating the raw hemp material to convert inactive cannabinoids

into their active forms. Rebellion CBD Co. employs decarboxylation to ensure the conversion of cannabinoid acids, such as CBDA (cannabidiolic acid), into CBD.

- Solvent Extraction:

One common method used by Rebellion CBD Co. for CBD extraction is solvent extraction. This method involves using a solvent, such as ethanol or hydrocarbon, to dissolve the CBD and other cannabinoids from the plant material. The solvent is then evaporated, leaving behind a concentrated CBD extract.

- CO2 Extraction:

Another extraction method utilized by Rebellion CBD Co. is CO2 extraction, which involves using carbon dioxide under specific temperature and pressure conditions to extract CBD. This method is highly efficient and allows for precise control over the extraction process, resulting in a high-quality CBD extract.

- Winterization:

After the extraction process, Rebellion CBD Co. employs winterization to remove unwanted impurities, such as waxes and lipids, from the CBD extract. This is achieved by mixing the extract with a solvent, typically ethanol, and subjecting it to low temperatures. The mixture is then filtered to separate the purified CBD oil from the impurities.

- Distillation:

Distillation is used to further refine the CBD extract obtained through solvent extraction or CO2 extraction. This process involves heating the extract to separate the different components based on their boiling points. By selectively evaporating and condensing specific compounds, Rebellion CBD Co. can obtain a highly purified CBD distillate.

- Isolation and Purification:

In some cases, Rebellion CBD Co. may isolate specific cannabinoids, such as CBD, from the distillate or extract using chromatography techniques. This allows for the production of CBD isolate, which contains only CBD and no other cannabinoids or plant compounds.

Testing and Quality Control:

Rebellion CBD Co. emphasizes the importance of rigorous testing and quality control measures to ensure the safety and potency of their CBD products. Third-party lab testing is conducted to verify the cannabinoid profile, confirm THC levels, and check for contaminants such as heavy metals, pesticides, and residual solvents.

- Third-Party Lab Testing:

By outsourcing lab testing to independent third-party laboratories, Rebellion CBD Co. ensures unbiased and accurate results. These tests provide transparency and give consumers confidence in the quality and purity of the CBD products.

- Cannabinoid Profiling:

Cannabinoid profiling is performed to determine the exact concentrations of cannabinoids present in the CBD extract or distillate. This allows Rebellion CBD Co. to accurately label their products and provide customers with precise information about the cannabinoid content.

- Purity and Contaminant Testing:

To ensure product safety, Rebellion CBD Co. conducts tests to check for contaminants, including heavy metals, pesticides, and residual solvents. This helps guarantee that their CBD products meet stringent quality standards and comply with regulatory requirements.

Product Formulation and Manufacturing:

Once the CBD extract or distillate has undergone testing and quality control measures, Rebellion CBD Co. focuses on product formulation and manufacturing.

- Full-Spectrum, Broad-Spectrum, and Isolate CBD:

Rebellion CBD Co. offers a range of CBD products, including full-spectrum, broad-spectrum, and isolate formulations. Full-spectrum CBD products contain CBD along with other naturally occurring cannabinoids, terpenes, and plant compounds. Broad-spectrum CBD products undergo additional processing to remove THC while retaining other beneficial compounds. CBD isolate products, on the other hand, contain only pure CBD.

- Choosing Carrier Oils and Other Ingredients:

Rebellion CBD Co. carefully selects carrier oils, such as MCT (medium-chain triglyceride) oil or hemp seed oil, to blend with the CBD extract or distillate. Additional ingredients, such as natural

Conclusion

The process of making hemp-derived CBD for Rebellion CBD Co. involves a meticulous approach from cultivation to extraction, testing, formulation, and compliance. By following strict standards, employing advanced extraction methods, conducting comprehensive testing, and prioritizing transparency and customer education, Rebellion CBD Co. strives to deliver high-quality CBD products that meet the needs and expectations of consumers. Understanding the intricacies of this process provides insight into the dedication and expertise required to create exceptional CBD products.

- Pine Bark Extract: Uses, Benefits, and Side Effects - July 11, 2023

- Process Of Making Hemp Derived CBD For Rebellion CBD Co. - June 9, 2023